AML3D strengthens US defence ties

23 August 2023

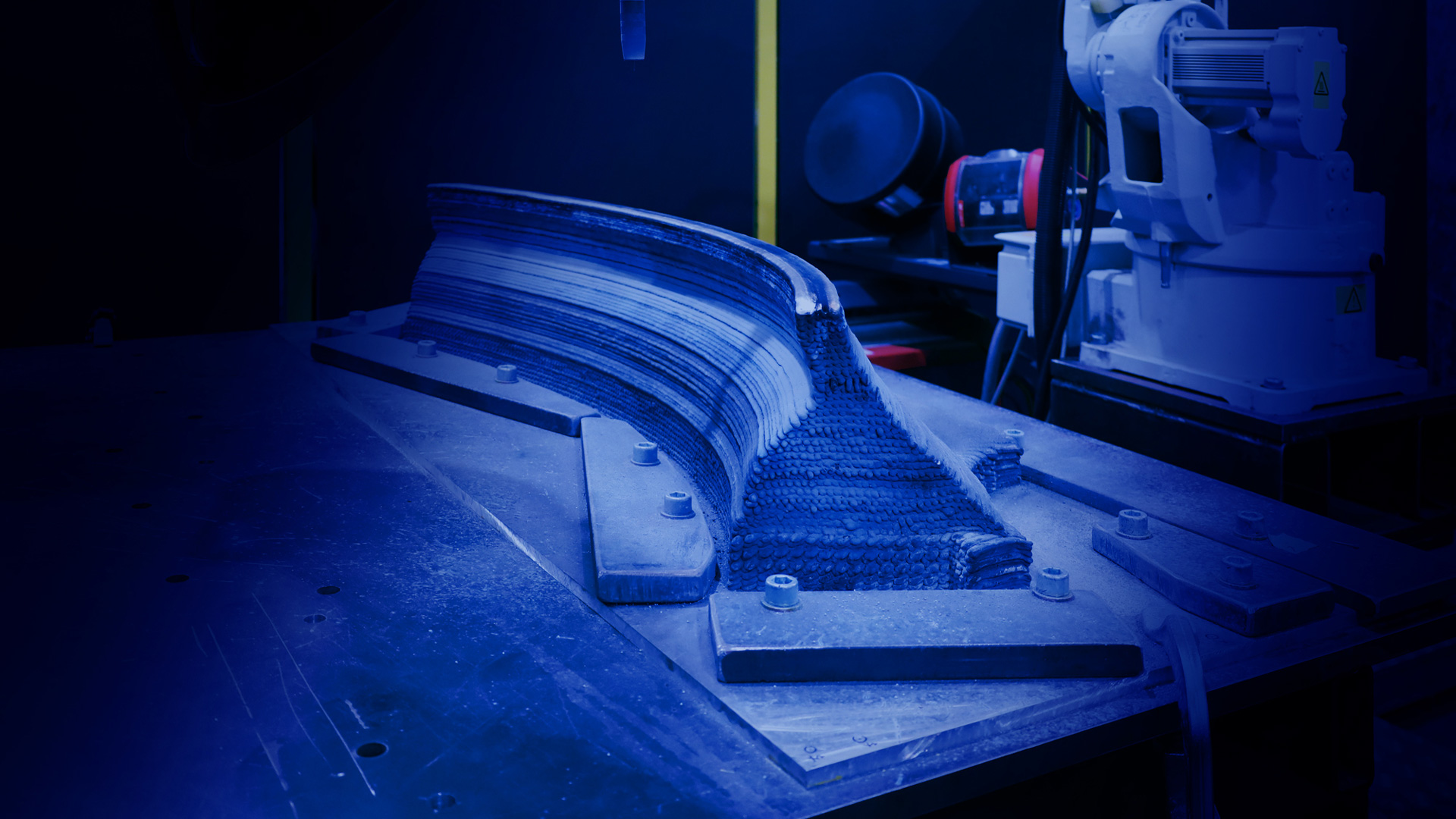

South Australian advanced manufacturer, AML3D, has announced it has signed a contract to manufacture high demand components for US Navy submarines.

The $2.02 million agreement with Blue Forge – a non-profit, neutral integrator supporting the sustainment of the US Navy’s submarine industrial base – will see AML3D develop and metal 3D print a replacement component used in US Navy submarines.

No longer available from traditional manufacturers, the ability for AML3D to metal 3D print the non-safety critical components for the ships solves a significant US supply chain challenge. Made with Nickel-Aluminum-Bronze alloy material, the contract also provides AML3D the opportunity to demonstrate the ARCEMY® Additive Manufacturing Technology’s ability to produce complex components to the highest standard.

AML3D’s Interim CEO, Sean Ebert, said AML3D is excited to deepen its long-term, strategic partnership with the US Navy’s submarine industrial base.

“The delivery of these complex submarine components, which is no longer available from traditional manufacturers, demonstrates the important role of AML3D’s ARCEMY technology at a time of heightened interest in advanced manufacturing to help meet demand driven by the AUKUS alliance,” said Mr Ebert.

“AML3D’s focus is on the US defence, aviation and maritime sectors and the Company is well positioned to access the many opportunities that will be created as a result of the AUKUS Alliance, in the US, Australia and Europe.”

This latest announcement follows earlier news that AML3D’s alloy testing contract with BlueForge Alliance has been extended.

Speaking to the extension of the alloy testing agreement, Mr Ebert said the contract is further evidence of the momentum of AML3D’s US scale up strategy and the ongoing development of a long-term, strategic partnership with the US Navy’s submarine industrial base.